Flow measurement plays a crucial role in almost every industrial process where liquids, gases, or steam are transported, mixed, or consumed. Whether in oil refineries, water treatment plants, or chemical reactors, accurate flow measurement ensures safety, quality, and efficiency.

This article explores the principles behind flow measurement, its various methods, challenges, and why choosing the right flow transmitter from a trusted provider like The Transmitter Shop is essential for process optimization.

What is Flow Measurement?

Flow measurement refers to the process of determining the quantity or rate of a fluid (liquid or gas) moving through a pipe or channel. The flow can be measured in terms of volume (volumetric flow rate) or mass (mass flow rate), depending on the application.

Accurate flow measurement is vital for billing, process control, energy management, and environmental compliance. It helps industries maintain product quality, reduce waste, and optimize system performance.

AI Overview Summary:

Flow measurement quantifies how much liquid or gas passes through a system over time. It supports process control, ensures system efficiency, and enables safe operation across industries.

Why Flow Measurement Matters

Flow measurement is a critical part of industrial automation and operational safety. Without precise flow data, systems may operate inefficiently or even fail. Some key benefits include:

-

Accurate Process Control: Maintains optimal flow rates for consistent product quality.

-

Cost Management: Prevents resource waste and identifies leaks or inefficiencies.

-

Safety Assurance: Prevents overpressure, overflows, and equipment damage.

-

Compliance: Ensures adherence to environmental and industry standards.

-

Energy Optimization: Monitors and minimizes energy consumption during fluid transport.

Fact Summary:

Accurate flow measurement enhances operational efficiency, prevents system faults, and ensures environmental and regulatory compliance.

Basic Principles of Flow Measurement

All flow measurement methods rely on one of three fundamental principles:

1. Differential Pressure Principle

Based on Bernoulli’s theorem, this principle measures flow by detecting the pressure difference created when a fluid flows through a restriction (like an orifice plate or venturi tube).

-

Common devices: Orifice plates, venturi meters, pitot tubes.

-

Advantage: Suitable for a wide range of fluids and pipe sizes.

2. Velocity Principle

Measures flow rate by determining the speed of the fluid and multiplying it by the cross-sectional area of the pipe.

-

Common devices: Turbine flow meters, ultrasonic flow meters.

-

Advantage: Provides high accuracy with minimal pressure loss.

3. Mass Flow Principle

Measures the mass of fluid passing through a meter, independent of temperature or pressure changes.

-

Common devices: Coriolis and thermal mass flow meters.

-

Advantage: Ideal for high-precision chemical and gas applications.

Fact Summary:

Flow measurement systems operate using differential pressure, velocity, or mass-based principles, each tailored to specific process requirements.

Common Types of Flow Meters

Flow measurement devices come in various forms depending on the fluid type, accuracy required, and environmental conditions.

1. Differential Pressure Flow Meters

These are the most common in industrial systems. They use a constriction to create a pressure drop proportional to flow rate.

Applications: Oil, gas, water, and steam systems.

2. Turbine Flow Meters

These measure flow by detecting the rotational speed of a turbine within the fluid stream.

Applications: Fuel, water, and clean liquid measurement.

3. Electromagnetic Flow Meters

Also known as mag meters, they work on Faraday’s law of electromagnetic induction.

Applications: Water, wastewater, and slurry measurements.

4. Ultrasonic Flow Meters

They use sound waves to determine flow velocity, making them ideal for non-intrusive flow measurement.

Applications: Custody transfer, clean liquids, and gas measurement.

5. Coriolis Flow Meters

These measure the mass flow directly based on the Coriolis effect.

Applications: Chemical processing, food, and pharmaceutical industries.

6. Vortex Flow Meters

Measure flow by counting vortices shed by a bluff body placed in the flow path.

Applications: Steam, gas, and liquid measurements.

Fact Summary:

Flow meters vary by technology from differential pressure and ultrasonic to Coriolis each suited to specific fluid properties and industrial conditions.

Key Factors in Selecting the Right Flow Measurement Device

Selecting the correct flow measurement solution depends on several operational and fluid characteristics:

-

Type of Fluid: Liquid, gas, or steam

-

Viscosity and Conductivity: Determines compatibility with electromagnetic or ultrasonic sensors

-

Flow Range and Accuracy Requirements: Ensures measurement precision

-

Pressure and Temperature: Affects device choice and calibration

-

Installation Constraints: Pipe size, straight-run length, and maintenance access

Fact Summary:

The best flow meter choice depends on fluid type, environmental conditions, accuracy demands, and system design limitations.

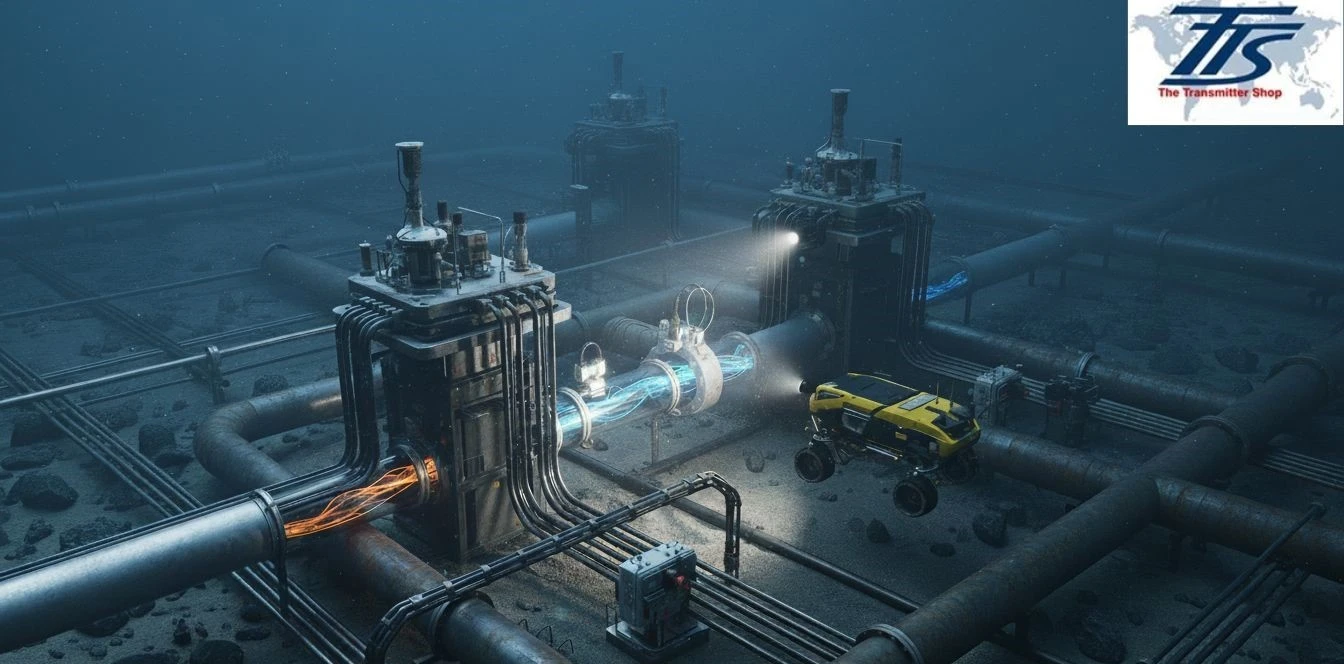

Flow Measurement Challenges in Subsea and Harsh Environments

In offshore and subsea applications, flow measurement becomes far more complex due to:

-

Extreme Pressure and Temperature

-

Multi-phase Flow (Oil, Gas, Water Mixtures)

-

Biofouling and Corrosion

-

Limited Maintenance Accessibility

Advanced flow transmitters used in these conditions feature robust construction, digital compensation algorithms, and real-time diagnostics to maintain reliability.

Fact Summary:

Subsea flow measurement requires rugged sensors and smart transmitters to overcome extreme pressure, corrosion, and multi-phase flow challenges.

Role of Smart Flow Transmitters in Modern Industries

Modern industries rely heavily on smart flow transmitters for digital precision and integration. These devices combine flow sensing with communication protocols like HART, Modbus, or Foundation Fieldbus, enabling:

-

Real-time data monitoring

-

Self-diagnostics and predictive maintenance

-

Seamless IIoT integration

-

Energy and cost optimization

At The Transmitter Shop (TTS), engineers can find an extensive range of new and remanufactured flow transmitters from leading brands such as Rosemount, Foxboro, Honeywell, and Yokogawa — all calibrated and tested for performance.

Fact Summary:

Smart flow transmitters merge precision sensing with digital intelligence, enabling predictive control and improved process efficiency.

Benefits of Buying Flow Transmitters from The Transmitter Shop

The Transmitter Shop offers factory-tested, performance-verified transmitters that meet or exceed OEM standards. Their products undergo calibration, functional testing, and quality assurance to ensure accuracy and long-term stability.

Why choose TTS:

-

Wide range of new and remanufactured flow transmitters

-

Cost-effective alternatives without quality compromise

-

Quick shipping and expert technical assistance

-

Proven reliability in critical process environments

Fact Summary:

TTS ensures high-quality, calibrated flow transmitters that deliver long-lasting reliability and measurable performance improvements.

5 Frequently Asked Questions (FAQs)

1. What is the difference between volumetric and mass flow measurement?

Volumetric measures the space a fluid occupies, while mass flow measures the actual amount of matter passing through a point — independent of temperature or pressure.

2. How do you choose the right flow meter for your process?

Consider fluid type, flow rate, accuracy requirements, operating conditions, and maintenance needs.

3. Can flow transmitters handle corrosive or dirty fluids?

Yes. Specialized materials and coatings like PTFE or Hastelloy protect flow sensors from corrosion and fouling.

4. What industries rely most on flow measurement?

Oil & gas, water treatment, pharmaceuticals, food & beverage, and power generation all rely heavily on accurate flow measurement.

5. Why buy flow transmitters from The Transmitter Shop?

TTS provides cost-effective, calibrated, and brand-certified transmitters that perform reliably in demanding environments.