Introduction

The US Electric Vehicle (EV) Motor Market is at the forefront of the nation’s clean mobility revolution, driving the transition from internal combustion engines to high-efficiency electric propulsion. As EV adoption accelerates, the demand for advanced electric motors—offering greater power density, lightweight design, and improved thermal management—continues to rise. These motors are essential for performance, range, and reliability in both passenger and commercial vehicles. With policy support, OEM investments, and consumer awareness around sustainability increasing, the US EV motor market is entering a phase of dynamic growth and technological transformation.

Market Drivers

One of the strongest growth drivers is the government’s commitment to net-zero emissions and green mobility. Federal incentives under the Inflation Reduction Act and state-level policies promoting EV adoption are accelerating motor demand. Automakers are investing heavily in in-house motor production to optimize performance and reduce dependency on third-party suppliers. The rapid expansion of EV charging infrastructure and advancements in motor efficiency, particularly permanent magnet synchronous motors (PMSM) and induction motors, are pushing the market forward. Rising fuel costs and consumer preference for low-maintenance electric vehicles also contribute to growing motor demand across both passenger and fleet segments.

Market Challenges

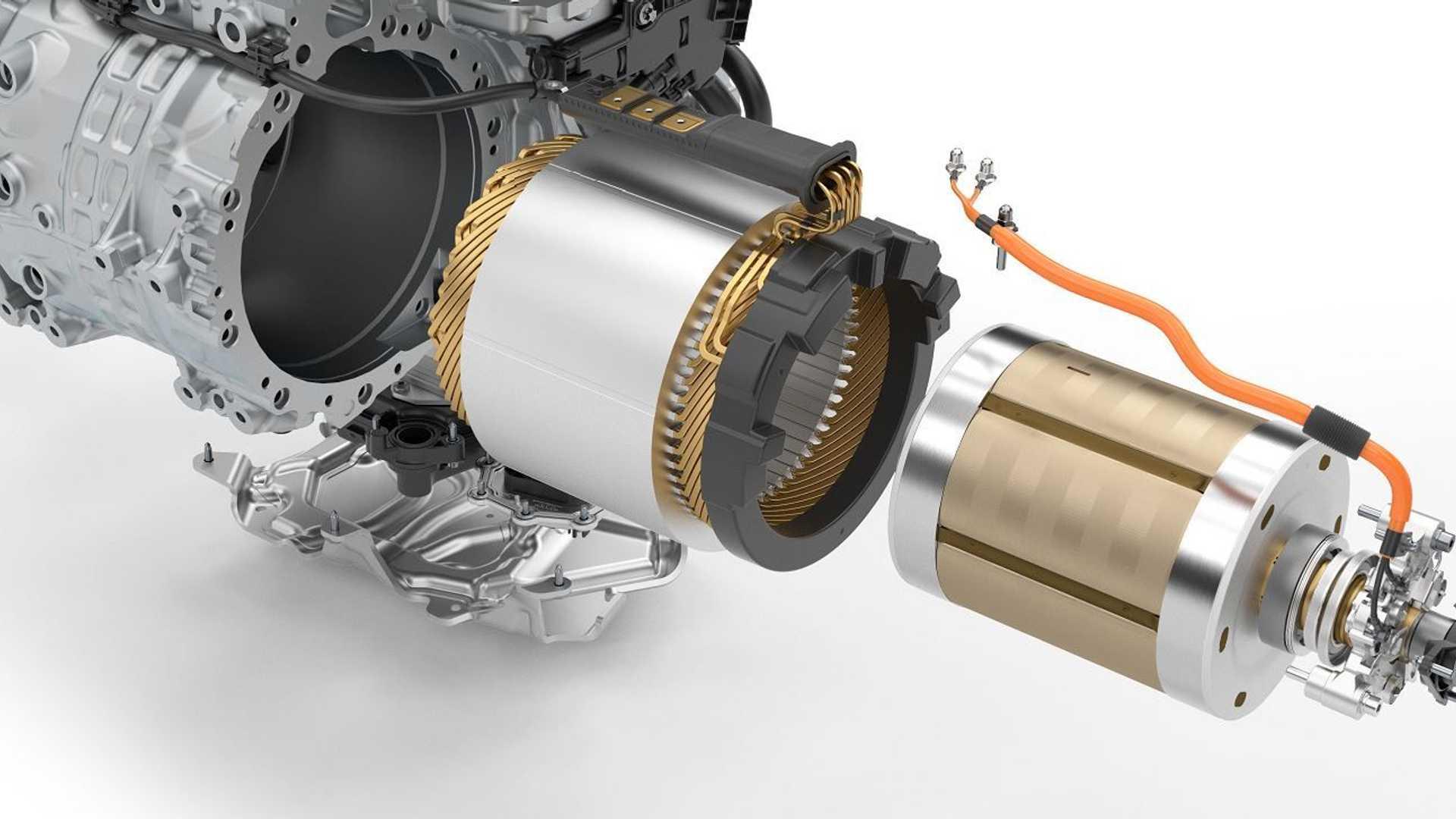

Despite robust growth, the industry faces key challenges related to cost, raw material dependency, and technological complexity. Permanent magnet motors rely on rare-earth elements like neodymium and dysprosium, whose supply chain remains volatile and concentrated in limited global markets. High manufacturing costs and thermal management issues also present barriers to scalability. Additionally, competition between motor types—such as switched reluctance motors (SRM) and PMSM—creates design trade-offs for OEMs balancing performance, efficiency, and cost. Integration with power electronics and inverter systems requires advanced engineering, further adding to development costs.

Market Opportunities

The shift toward localized motor production in the US presents a major opportunity for domestic suppliers. Companies are focusing on developing rare-earth-free motors using innovative designs and advanced magnetic materials. Electric commercial vehicles, including delivery vans and trucks, are emerging as new growth frontiers for motor manufacturers. Furthermore, the evolution of solid-state batteries and high-voltage architectures enhances the potential for next-generation motors with improved torque and energy conversion efficiency. Strategic partnerships between OEMs and technology firms are paving the way for integrated propulsion systems that enhance performance while minimizing weight and energy loss.

Regional Insights

The Midwest and Southern regions of the US—home to major automotive manufacturing hubs like Michigan, Ohio, and Tennessee—are becoming central to EV motor production. California remains a key market due to strong EV adoption rates and progressive environmental policies. States such as Texas and Georgia are witnessing new investments from automakers and motor manufacturers setting up localized facilities to meet domestic demand. The proximity to critical supply chains and growing EV infrastructure further strengthens the regional ecosystem supporting the EV motor industry.

Future Outlook

The future of the US Electric Vehicle Motor Market is shaped by rapid innovation, policy-driven expansion, and industry consolidation. Advancements in axial flux and dual-rotor designs will improve efficiency and power output while reducing size and weight. As OEMs focus on vertical integration, many will design proprietary motors optimized for specific vehicle architectures. The push toward sustainability and circular manufacturing will also drive recycling initiatives for magnets and copper materials. By 2032, the market is expected to be dominated by high-performance, cost-efficient, and domestically manufactured EV motors, supporting the nation’s long-term transition to fully electric mobility.

Conclusion

The US EV Motor Market stands as the backbone of America’s electrified transportation ecosystem, linking innovation, efficiency, and sustainability. While challenges persist in material costs and engineering complexity, the industry’s commitment to decarbonization and performance excellence remains unwavering. As government incentives, R&D investments, and consumer adoption continue to rise, the next decade will witness a transformation in how electric motors redefine mobility. From advanced designs to eco-friendly materials, these innovations will power the vehicles of the future and drive the nation toward a cleaner, smarter automotive era.